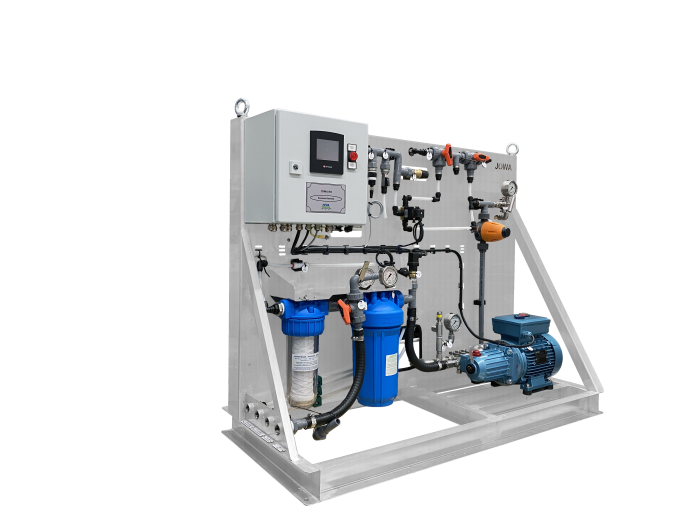

JOWA RO Water Maker - Reverse Osmosis system 3,2T-5,5T SEA

Modular plug & play system for easy installation

High pressure piping system in SS316L material

Direct driven high-pressure pump SS316L

Salinity control system with automatic 3-way valve

Auto flush system after each stop, via active carbon filter

Hi-Flow 20” 5micron feed water filter

Communication features: TCP/IP, MODbus, CANbus, RS232, RS485, USB and more

High quality HMI colour touch graphic display

All in one skid solution

Show detailed description

JOWA RO reverse osmosis Pre/post treatment and options

- Pre-filter mulitlayer bed AFM green glass system for best performance

- CIP cleaning tank

- Re-hardening filter

- Dosing Equipment for anti-scalant, chlorine and more

- UV sterilizer or Silver Ion Sterilizer

- Feed pump or Feed valve

- Second pass system for technical water <10ppm

- CO2 dosing system

Functions

Reverse osmosis desalination is among the finest levels of filtration available. The RO membrane generally acts as a barrier to all dissolved salts and inorganic molecules. Water molecules, on the other hand, pass freely through the membrane creating a purified product stream. Rejection of dissolved salts is typically 98% depending on factors such as membrane type, feed composition, temperature, and system design.

Capacity is 3,3T or 5,5T potable water per day. Continuously monitoring and automatically divert the product flow depending on salinity value. Full production with a temperature between 6-35C° and TDS 35 000ppm (salinity).

Unique design with top quality HDMI interface. User friendly touch screen and prepared for communication to ECR/AIS via PROFIbus, CANbus, MODbus and more

Product Inquiry

Brochure

Video